Autonomous Swarm Robots for Delivery System

Date: Fall 2015 | Category: Personal Projects | Affiliation: K.S. Institute of Technology

Develop cheaper and modular robots for dynamic task assignment in warehouse and assembly line delivery system.

Dependencies:

Overview

The artificial swarm intelligence has been inspired by biological studies of behaviour of ants, bees, wasps and termites. This behaviour and flawless co-ordination have been the spark for changing the perspective on how robots were understood, thereby giving a new trend to their functionality - such as solving problems through large population.

This highly adaptable and self-organized system of robots is a new approach to co-ordination of multi robot systems. It offers a different kind of material handling and boasts of a complete warehouse solution. It is driven by the following objectives- firstly that the products should be able to organize themselves. Secondly, the same piece of equipment should be able to handle all products irrespective of their complexity. Thirdly, it should have multiple degrees of flexibility and adaptability and should be able to handle materials effectively during peak seasons. Lastly, the requirements should be fulfilled when the customer wants them and as early as possible.

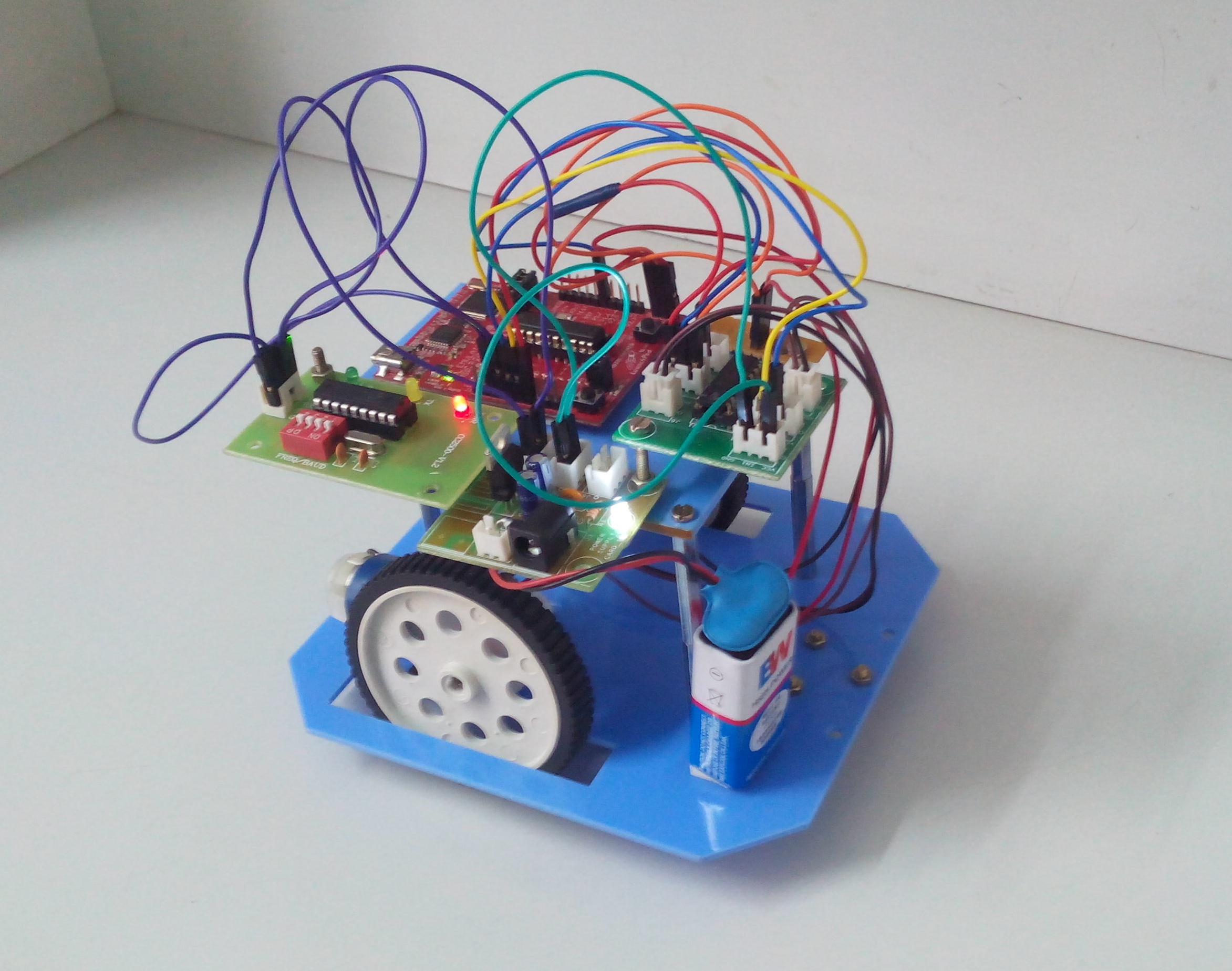

Figure 1. Prototype of the Swarm Robot

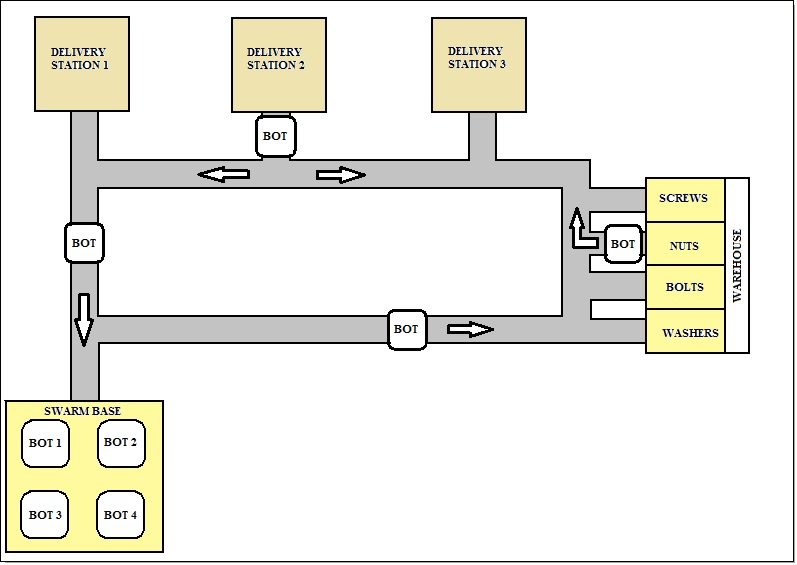

Figure 2. Schematic of Simulation/Controlled Field Operation Area

Dynamic Model of the Robot

The robots which are used to achieve this functionality consists of The Texas Instruments MSP430 family of ultralow-power microcontrollers mounted on the top. It forms the heart of the robot system, consists of several other devices featuring different sets of peripherals targeted for various applications. The architecture, combined with five low power modes, is optimized to achieve extended battery life in portable measurement applications. The device features a powerful 16-bit RISC CPU, 16-bit registers, and constant generators that contribute to maximum code efficiency. Hence this solves the major problem faced in adaptability as new algorithms can be implemented easily with multi-thread processing. The digitally controlled oscillator (DCO) allows wake-up from low-power modes to active mode in less than 1 μs, thus having very high response time. MSP430G2253 series are very low cost ultra-low-power (1.8 V to 3.6 V) mixed signal microcontrollers with built-in 16-bit timers, up to 24 I/O capacitive-touch enabled pins, a versatile analog comparator, and built-in communication capability using the universal serial communication interface. In addition, the MSP430G2x53 family members have a 10-bit analog-to-digital (A/D) converter.

Swarm Robots in Action

Delivery Stations and Storage Units/Warehouse

Advantages

This robotic fulfillment system enables extremely fast cycle times, from receiving to picking to shipping. The system is completely commutable, which means that you can start a business with a small system addressing primary needs, and add robotic systems and other supporting gear as your business grows. The size of the robots isn’t one of the constraints as it should possess enough mechanical power for heavy lifting. The result is a building that is quick and low-cost to set up, inexpensive to operate and easy to change anywhere in the world. Offers complete industrial delivery solution.